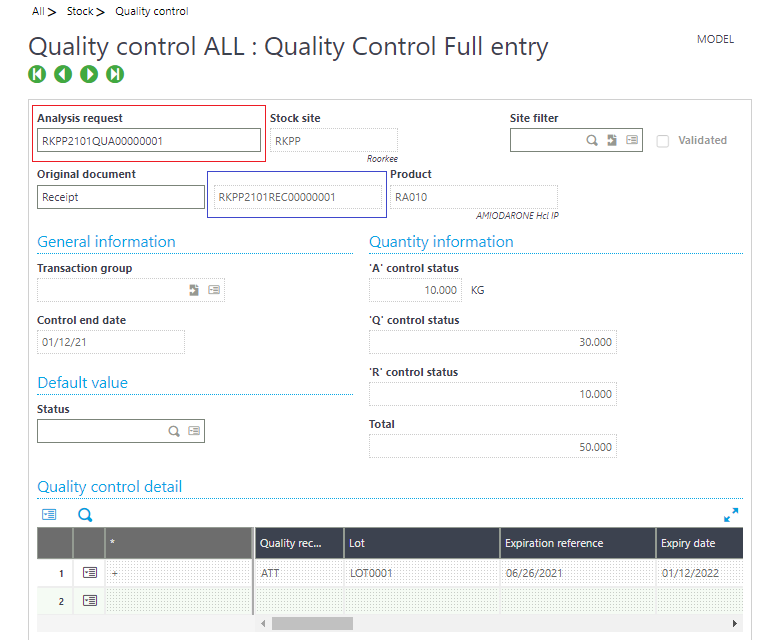

Sage X3 provide us a feature of processing automatic signature for a record if the record is created or modified by the first level of user present in assignment rule. This means if we have ADMIN as first user to sign a record and if ADMIN himself creates or modifies the record, that particular record will get signed automatically. The user will not have to manually go and perform the signature. You will able to see the record signed and processed to second level user for signature in workflow history. But is some cases user may need to restrict this automatic signature. For example if a user creates a record and need to do some modifications before singing that particular record, in this case user will have to restrict the standard’s automatic signature. Below we will see how we can restrict standard to perform the automatic signature in workflow.

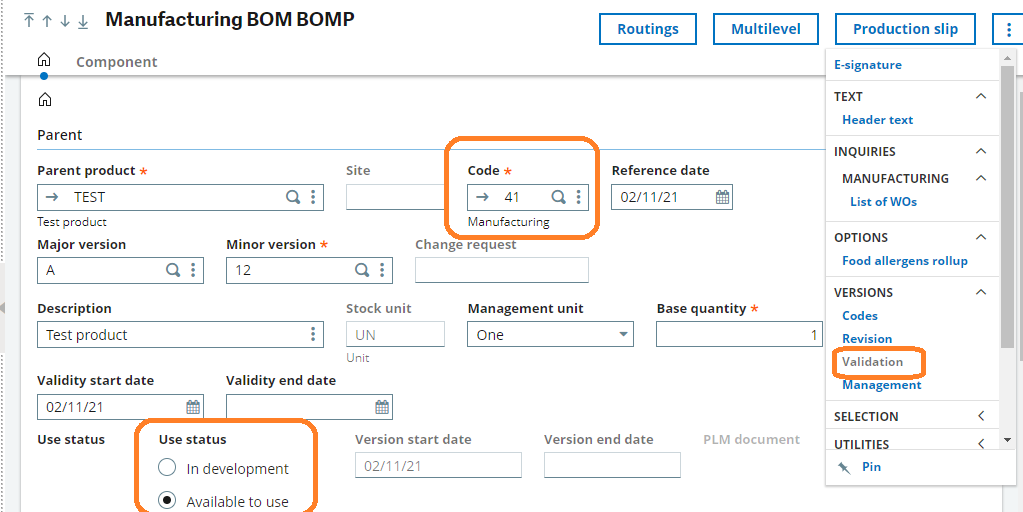

In the below screenshot we can see the first level of user in assignment rule is ADMIN.

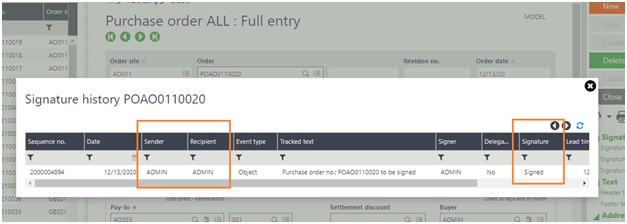

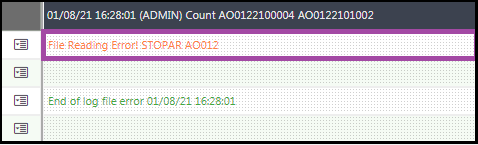

Now when we create the purchase order with user ADMIN the standard will not ask user for signature, it will perform the automatic signature as shown in below screenshot.

To restrict the automatic signature we will have to change the setup in workflow rule. Kindly refer the below steps.

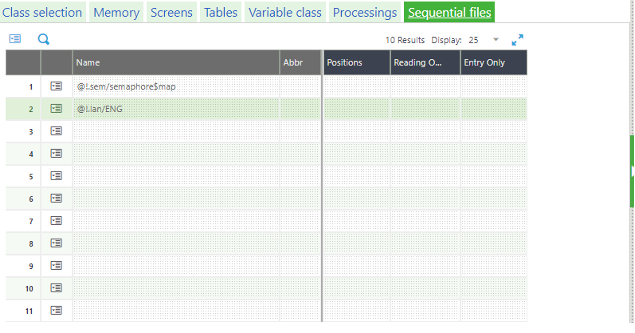

Navigate to workflow rules and select the workflow of the object for which we want to restrict the automatic signature.

Navigate: SETUP -> WORKFLOW -> WORKFLOW RULE

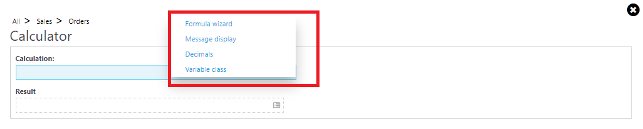

Select the ACTION tab from the workflow window. Here we will be able to see what actions are triggered when the workflow is executed. Also we can see the which action is triggered at what phase of workflow and the action’s execution condition, which means at what condition the action will get triggered.

You will be able to see an action named SIGWRK in three different lines of the grid as shown in the below screenshot.

From these three lines you will have to delete the action which has “VAL” in it parameter value as shown below. To check the parameter values just click on the line for which you need to check the parameter and you will be see its value in the parameter tab which is located just below the action grid.

The reason behind deleting this action is the action is used to sign the record which is the created by first level of user.

Another change we have to do is with DIVPOHAPP1 action. We just have to change the execution condition for this action from “[L]USER<>GUSER & [L]USER<>[F:PSH]REQUSR & S_NBRUSR>0″ into “S_NBRUSR>0”.

The reason behind changing the execution condition for this action is this action updates the purchase order signature status. Hence we will be able to restrict the automatic signature.

Hence, when we make above two changes in workflow rules the automatic signature which get restricted and when the first level user creates or modifies the record he will be able to perform the signature for that particular record.

About Us

Greytrix – a globally recognized and one of the oldest Sage Development Partner is a one-stop solution provider for Sage ERP and Sage CRM organizational needs. Being acknowledged and rewarded for multi-man years of experience, we bring complete end-to-end assistance for your technical consultations, product customizations, data migration, system integrations, third-party add-on development and implementation competence.

Greytrix caters to a wide range of Sage X3, a Sage Business Cloud Solution, offerings. Our unique GUMU integrations include Sage X3 for Sage CRM, Salesforce.com, Dynamics 365 CRM and Magento eCommerce along with Implementation and Technical Support worldwide for Sage X3. Currently we are Sage X3 Implementation Partner in East Africa, Middle East, Australia, Asia, US, UK. We also offer best-in-class Sage X3 customization and development services, integrated applications such as POS | WMS | Payment Gateway | Shipping System | Business Intelligence | eCommerce and have developed add-ons such as Catch – Weight and Letter of Credit and India Legislation for Sage X3 to Sage business partners, end users and Sage PSG worldwide.

integrations include Sage X3 for Sage CRM, Salesforce.com, Dynamics 365 CRM and Magento eCommerce along with Implementation and Technical Support worldwide for Sage X3. Currently we are Sage X3 Implementation Partner in East Africa, Middle East, Australia, Asia, US, UK. We also offer best-in-class Sage X3 customization and development services, integrated applications such as POS | WMS | Payment Gateway | Shipping System | Business Intelligence | eCommerce and have developed add-ons such as Catch – Weight and Letter of Credit and India Legislation for Sage X3 to Sage business partners, end users and Sage PSG worldwide.

Greytrix is a recognized Sage champion ISV Partner for GUMU Sage X3 – Sage CRM integration also listed on Sage Marketplace; GUMU

Sage X3 – Sage CRM integration also listed on Sage Marketplace; GUMU integration for Sage X3 – Salesforce is a 5-star rated app listed on Salesforce AppExchange and GUMU

integration for Sage X3 – Salesforce is a 5-star rated app listed on Salesforce AppExchange and GUMU integration for Dynamics 365 CRM – Sage ERP listed on Microsoft AppSource.

integration for Dynamics 365 CRM – Sage ERP listed on Microsoft AppSource.

For more information on Sage X3 Integration and Services, please contact us at x3@greytrix.com, We will like to hear from you.

![[Product Master]](http://www.greytrix.com/blogs/sagex3/wp-content/uploads/2021/01/Product-Master-1024x556.jpg)

![[Product Site - Costing Method]](http://www.greytrix.com/blogs/sagex3/wp-content/uploads/2021/01/Product-Site-Method-1024x364.jpg)

![[Product Site - Standard Cost]](http://www.greytrix.com/blogs/sagex3/wp-content/uploads/2021/01/Product-Site-Standard-Cost-1024x345.jpg)

![[Miscellaneous Receipt Example - 1]](http://www.greytrix.com/blogs/sagex3/wp-content/uploads/2021/01/Miscellaneous-Receipt-1-1024x538.jpg)

![[Miscellaneous Receipt Example - 2]](http://www.greytrix.com/blogs/sagex3/wp-content/uploads/2021/01/Miscellaneous-Receipt-2-1024x533.jpg)

![[Report Dictionary-1]](http://www.greytrix.com/blogs/sagex3/wp-content/uploads/2021/01/Jan-Blog-1-1024x514.png)

![[Report Dictionary-2]](http://www.greytrix.com/blogs/sagex3/wp-content/uploads/2021/01/Jan-Blog-2-1024x457.png)

![[Custom Data type - ZWST]](http://www.greytrix.com/blogs/sagex3/wp-content/uploads/2021/01/Jan-Blog-3-1024x467.png)

![[Report Dictionary - 3]](http://www.greytrix.com/blogs/sagex3/wp-content/uploads/2021/01/Jan-Blog-4-1024x424.png)

![[Work center finder]](http://www.greytrix.com/blogs/sagex3/wp-content/uploads/2021/01/Jan-Blog-5-1024x599.png)